ratter

New member

Episode 1 can be found here.

Let's tackle Episode 2.

This one is still very much in progress so it will have to play out over the coming weeks but a lot is already done.

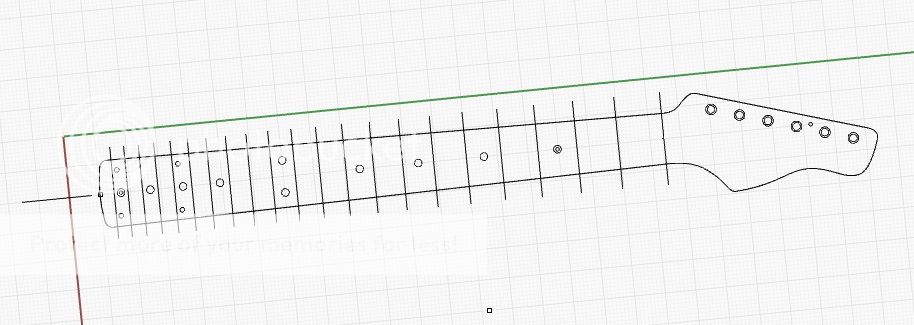

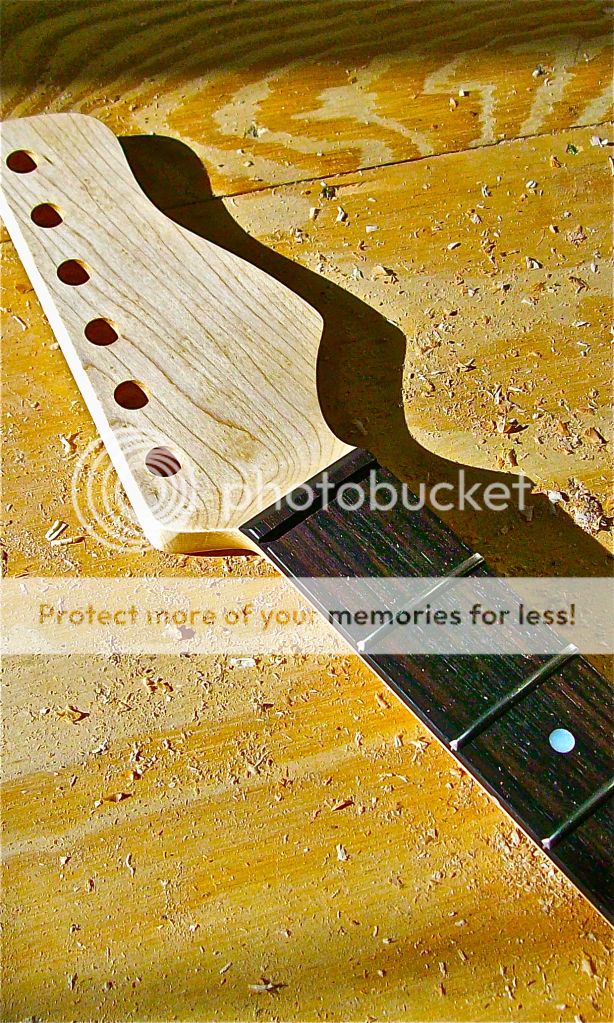

Episode 1 was a pretty bog-standard Tele copy. This time we're going off the reservation a little bit and building a strat style with my own original body and headstock shapes. We'll go from raw wood all the way through to case candy.

The target is a takeoff on a mid to late 60's style rosewood board strat. But that's just a rough starting point.

The targeted specs are:

Alder body

Maple neck with rosewood board

Thin C shape, 21 frets, MOP dot inlays

6-screw vintage trem

Either SSS or HSS...haven't decided yet

First step...the neck...

Let's tackle Episode 2.

This one is still very much in progress so it will have to play out over the coming weeks but a lot is already done.

Episode 1 was a pretty bog-standard Tele copy. This time we're going off the reservation a little bit and building a strat style with my own original body and headstock shapes. We'll go from raw wood all the way through to case candy.

The target is a takeoff on a mid to late 60's style rosewood board strat. But that's just a rough starting point.

The targeted specs are:

Alder body

Maple neck with rosewood board

Thin C shape, 21 frets, MOP dot inlays

6-screw vintage trem

Either SSS or HSS...haven't decided yet

First step...the neck...