BesaMoogie

Well-known member

Hi guys, I need some help with a Randall RM50 and how to proceed with the problem.

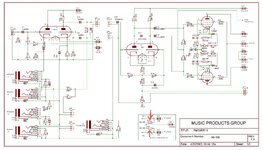

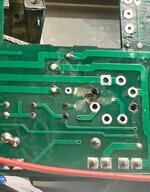

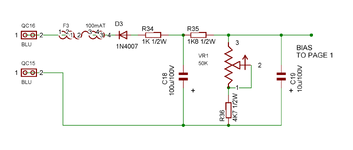

It look likes, the heater supply was "overloaded" causing tow 100R 1W resistors to blow. Have a look on the schematics and pictures I attached. The resistors are located at the bottom right of the schematic.

The amp blow its main fuse. Replacing the fuse just causes to blow it again.

I`m a bit hesistant to just replace the two blwon resistors and power it up again. So what could cause this problem and what is the best way to trouble shoot this?

Is there possibly a short in the PT overlaoding the HT supply?

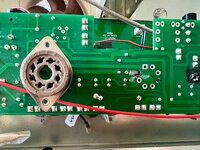

Would taking out the PT and checking first be the way to go?

So far I checked the Output tubes and they are ok, I don`t have the preamp tubes to check.

The Chassis/Ground connection (see schematic) is ok as well.

Thanks!

It look likes, the heater supply was "overloaded" causing tow 100R 1W resistors to blow. Have a look on the schematics and pictures I attached. The resistors are located at the bottom right of the schematic.

The amp blow its main fuse. Replacing the fuse just causes to blow it again.

I`m a bit hesistant to just replace the two blwon resistors and power it up again. So what could cause this problem and what is the best way to trouble shoot this?

Is there possibly a short in the PT overlaoding the HT supply?

Would taking out the PT and checking first be the way to go?

So far I checked the Output tubes and they are ok, I don`t have the preamp tubes to check.

The Chassis/Ground connection (see schematic) is ok as well.

Thanks!